Wire EDM Bandsaw

July - December 2024

Before my final semester at Northeastern, I had been getting a bit obsessed with wire EDM machines. I was even considering building one myself, so you can imagine I was excited to see that one of the available capstone projects was to build custom wire EDM machine! The market for WEDM machines is dominated by extrememly capable machines with 6 figure price tags, and we had around 1/20th of that budget. In order to finish the project within a few months and on budget, we addressed a niche use case that required a smaller, much different set of requirements.

Client’s requirements

- Cut a metal 3D printed (DED) part off of a 18” build plate - previously a bandsaw or angle grinder was used

- Cuts must be flat within ±.020”

- Adjustable cut height

- Affordable (<$3000 w/o power supply)

Responsibilities

- Work with group of 6 to brainstorm novel format of Wire EDM machine

- Design X/Z axis, wire tensioning, end effector subassemblies

- Lead design and build of machine over extreme timeline

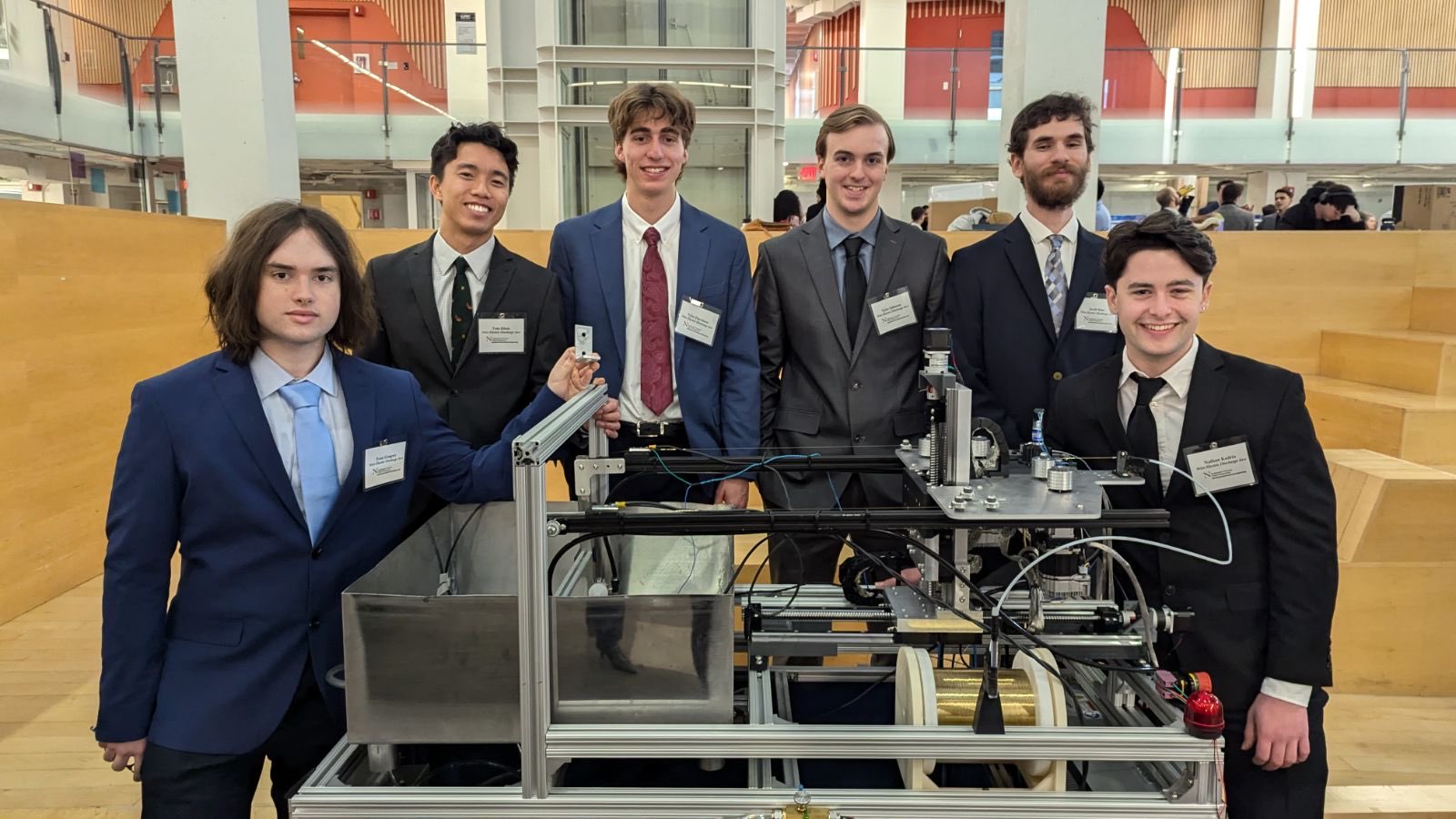

Capstone day group pic

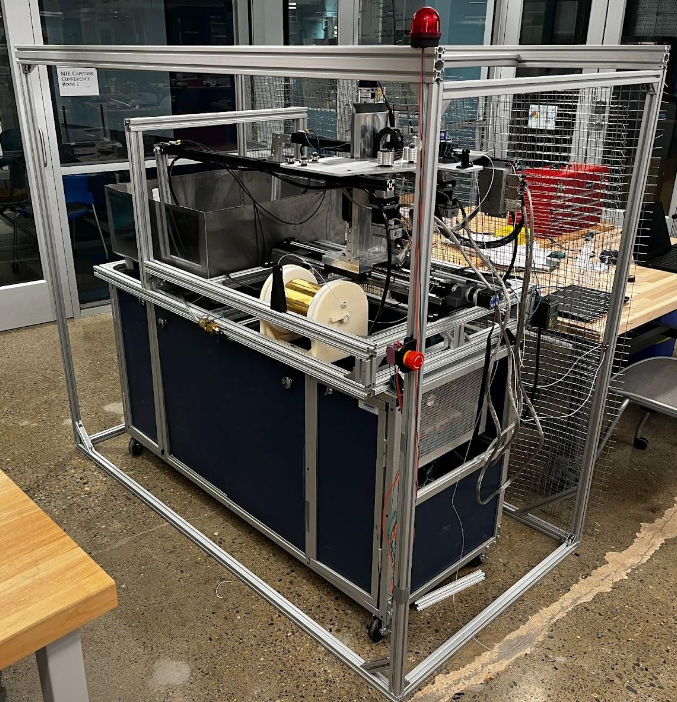

Full system

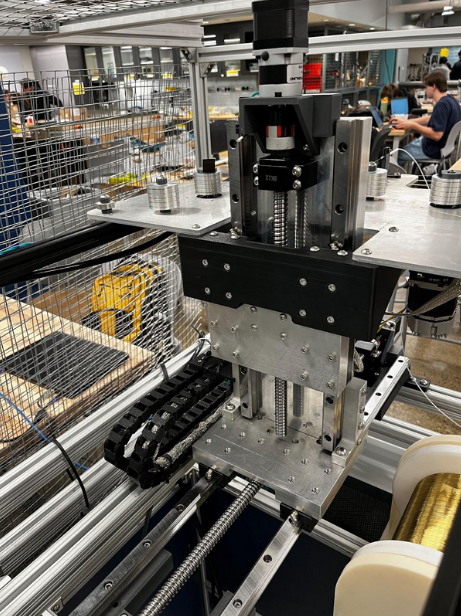

Subsystem: X/Z Stage and Wire tensioning

- X/Z stage driven with geared stepper motors and EtherCAT drivers

- Hand calculations used to determine vertical displacement of wire due to X axis flex

- 2 servos run closed loop with load cell to control wire tension and speed

- Wire tensioning was inconsistent, so a planetary reduction was added to servos to increase precision and torque

- Further iteration necessary to reduce skipping on output wire tensioning assembly

Wire tensioning test

X/Z Stage

Subsystem: End Effectors

- End effectors were suspended on cantilevered beams to reach through 18” diameter build plate

- Water blocks mount diamond wire guides, nozzles, pulleys, and NPT fittings

- CFD used to determine correct nozzle orifice size, hand calculations used to determine necessary post-pump pressure

- End effector designed to be extremely compact in order to fit around workpiece in COTS stainless steel tank, significantly reducing cost

- Machinability of water block was crucial, as it was done in-house

- More bracing on end effectors was added to deal with inconsistent wire tension

Nozzle/water block pressure test

Water block - my favorite part on the machine

What I Learned

- On large projects, splitting up the system and doing subsystem testing is critical

- Test early and often

- There is always a way - even if it’s me buying a 3D printer with personal funds and running it around the clock to make stand-ins for machined parts

- Good project management means communicating failures early and delegating work, even if I’d prefer to do it myself

- Any engineering assumption made will be tested and could cause failures